.

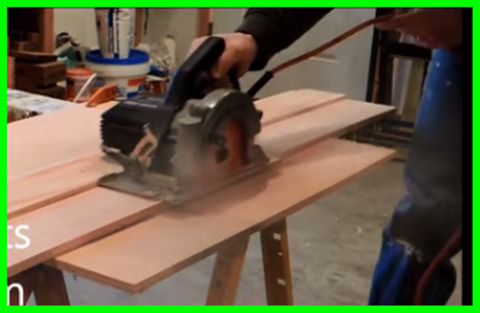

The Must Have Circular Saw Jig

Now if you are cutting across the grain of your finished piece you could get some grain tear out on the top surface and at the far end of the cut because the saw blade teeth are rotating out of the wood on these two surfaces.

The way to solve this problem is to set up your jig on the line you want to cut and the score the surface of the material being cut with your utility knife, using the jig to guide your utility knife. At the end I use my combination square as a guide for the utility knife cut.

.

Pages: 1 2

I’ve used this technique for many years. It works great and is also easier to cut whole sheets of plywood than struggling with a table saw.

Well I do not know how else you would cut a straight line with a hand saw, unless you had a guide to do it with!!!

Made one a few days ago.

2-4″ rigid foam insulation and that jig and you have a cheep easy panel saw. I’ve built hundreds of cabinets in driveways that way.

Ive got an eight ft. And a four ft.

Or buy a track saw

Tony Panici joey skubby made this video

Real funny Adam Post I invented this in 1875

This is a very old and often used technique. Simple quick and inexpensive.

Easiest jig to make!

I don’t know why I’ve never made one of these. I’ll do so this weekend.

Amazing alright!!!! Amazing how he took two minutes worth of information and made a 9+ minutes video.

…buy a Festool.

Not amazed

EIGHTEEN 75??? Good going old timer…!!

I own a track saw now but used this technique for years.

Damn I’m getting old^